Use single-image applications and continuous designs for efficient finishing

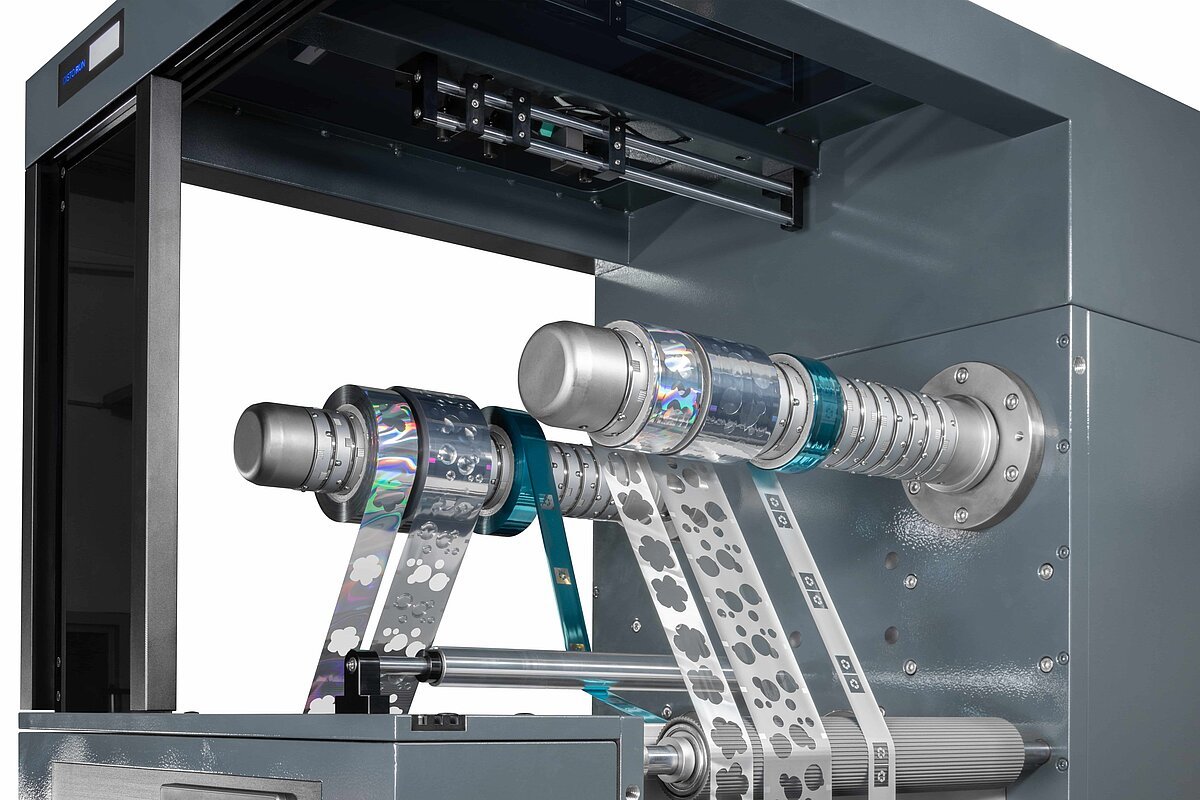

Efficient, sustainable, and commercially viable: Without sacrificing design, the KURZ DISTORUN® cold transfer module, available locally through Synchron Markings, reduces costs and saves resources. The film-saving device allows for the reuse of free surfaces on transfer products that have already undergone processing and can be used to produce single-image and continuous designs.

Easy expansion for label finishing on flexographic printing lines

KURZ’s DISTORUN® creates new opportunities. The stand-alone transfer unit can both preserve transfer goods and enable single-image applications on flexographic printing machines, in contrast to traditional cold transfer modules. Compact, standalone, build-on transfer unit DISTORUN® works independently of the flexographic printing machine’s control system. The module follows the printing speed and is mounted on the machine’s rail system. This makes it possible to apply continuous and single-image designs effectively.

“Efficiency and flexibility are essential for the competitiveness of our customers on the market. Our DISTORUN® transfer device fulfils both criteria,” comments Jochen Wening, Head of Sales and Project Management, Business Area Machines and Applications Security Field at KURZ.

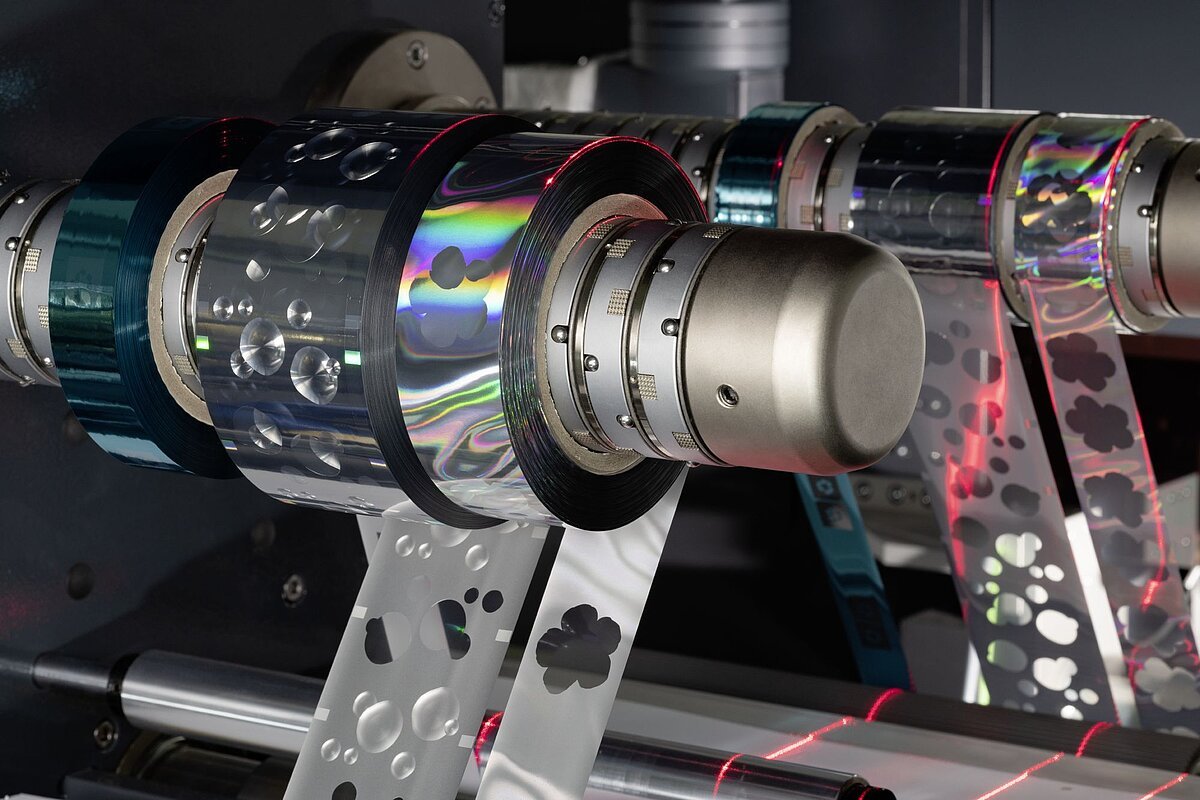

In addition to standard designs, KURZ’s innovative single-image application technology also ensures full flexibility in individual label design. For example, the breath-taking and brilliant TRUSTSEAL® SFX 3D effects from KURZ can be used to create distinctive, customer-specific designs with striking metallisation.

Focus on efficiency and sustainability

Being a pioneer in the industry of surface finishing, KURZ also values sustainability with DISTORUN® while maintaining the highest standards of performance and design.

The cold transfer module is equipped with state-of-the-art servo control and sensor technology, and specially designed software enables individual positioning so that individual transfer images can be precisely arranged. The free surfaces of the already processed transfer product can therefore be used for further finishing passes. As each roll is used efficiently several times, less waste is generated and consumables are used more sparingly. In this way, the sustainability balance of print products can be optimised with the KURZ foil-saving system with no compromise on design and performance.

Jochen also reiterates that using free space on already processed transfer products enables customers to save valuable consumables and to benefit from highly efficient, resource-conserving further processing.

Advantages of the DISTORUN® cold transfer unit at a glance:

- Cost-effective saving of transfer products

- Transfer products can be reused and retain their perfect fit

- For single-image and continuous designs

- No machine modifications necessary

- It can be synchronised with the flexographic printing machine

- Different positionings possible on the flexographic printing machine

- Foil tension control during unwinding and winding

- Available dimensions: 330 mm, 420 mm, and 520 mm width for one, two or three film webs.

KURZ is a one-stop shop

Due to the increase in digital applications and machines worldwide, it has been necessary for KURZ to look at developments in this category. The high demand for sustainable metallised finishing of products, as well as the demand for smaller runs, both in the sheetfed and flexo markets, has increased, and KURZ has developed a range of machines for these applications. Synchron Markings in support of these markets, is proud to represent KURZ.

These include 2D and 3D stand-alone machines that can be customised to fit the requirements of current digital printing machines, and are part of the production process in printing factories. KURZ is a one-stop shop supplying machinery for the either upstream or downstream application of metallisation and supplies the software, and consumables for these applications. Please contact your local Synchron offices for further information.

© Synchron Fabrics & Foils, March 2023

It’s simple really. The better the packaging the better the perceived value. KURZ foils provides our brand with a direct route to the “buying brain” – and it shows on the bottom line…

![]()

Synchron Fabrics & Foils for Brand Enhancement

cs@synchron.co.za • +27 21 527 7100

Accreditation downloads: BBBEE Certificate and ISO 9001